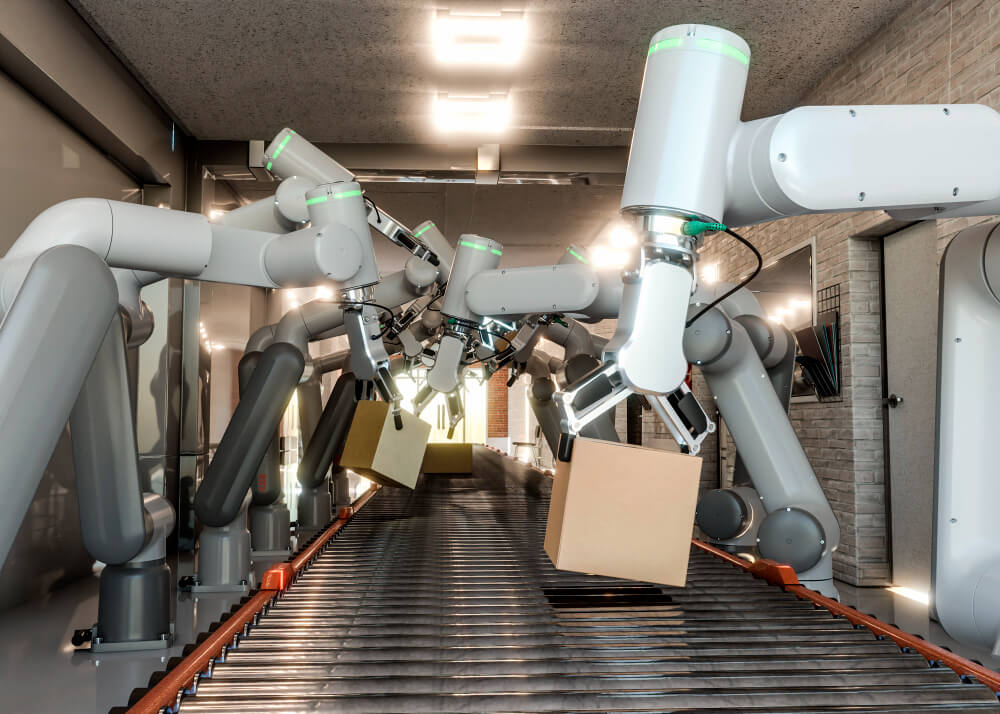

In modern manufacturing, floor space is more than real estate — it’s potential. As production lines become more complex and demand increases, businesses are looking upward for answers. Enter the overhead conveyor system: a space-saving, cost-effective, and productivity-enhancing solution that’s changing the way factories operate.

At Dynamic Industries, we’ve seen how overhead systems can unlock space, streamline workflows, and reduce manual handling, all without expanding your facility’s footprint.

Why Overhead Conveyors?

Overhead conveyors offer distinct advantages that traditional floor-level systems simply can’t:

- Maximized Floor Space: Free up ground-level space for workers, packaging, or storage.

- Improved Safety: Reduce clutter and forklift movement for a safer work environment.

- Continuous Flow: Keep materials in motion with fewer bottlenecks.

- Versatility: Handle everything from lightweight cartons to heavy parts with tailored engineering.

Real-World Impact: 40% Faster Turnaround in Assembly

One of our recent installations involved a Tier 2 automotive supplier facing assembly delays due to congested workstations. By integrating a modular overhead conveyor system, we:

- Increased throughput by 40%

- Reduced material transport time by 60%

- Improved ergonomic conditions for operators

The result? Faster shipping, fewer errors, and a safer, more productive workspace.

Designed for Your Process

Our overhead systems can be configured with:

- Power & Free Tracks (for selective routing)

- Cleanroom & FDA-grade components (for food/pharma clients)

- Modular add-ons (for future growth or layout changes)

Dynamic Industries engineers work closely with clients to tailor every inch of the system to your exact operational needs.

Build Up, Not Out

Instead of expanding your factory’s footprint or investing in costly renovations, consider how overhead solutions can transform your current space into a smarter, more scalable production hub.